Quality on Time!

Why use Venator for your precision grinding?

It’s in our name…

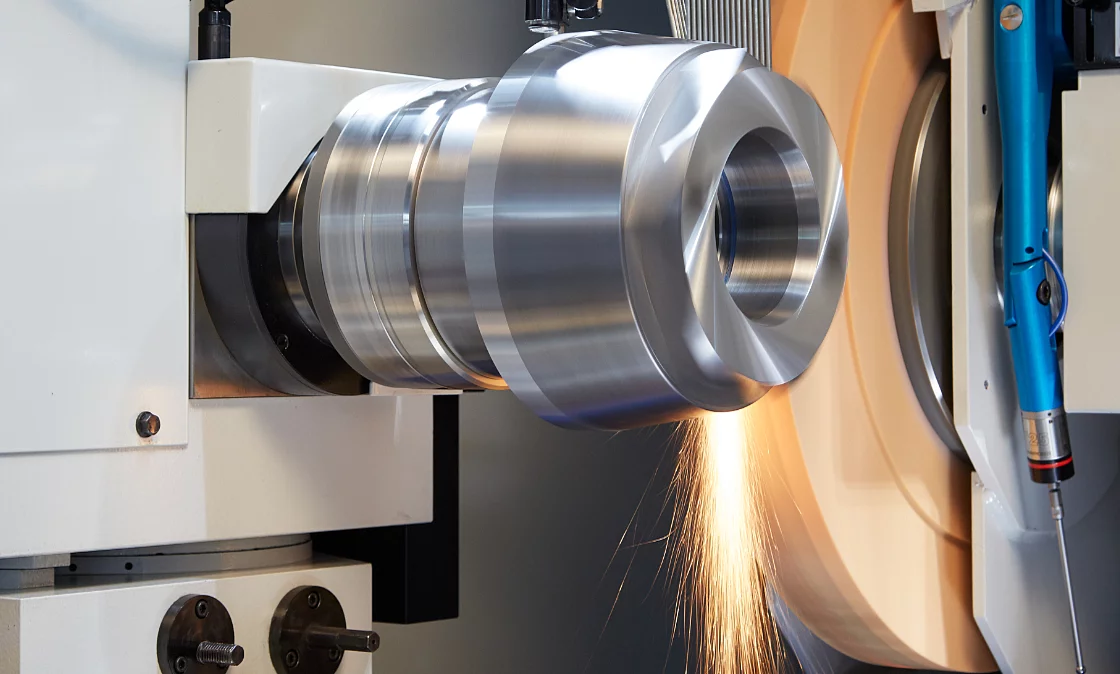

Because precision and on-time delivery are the cornerstones of our service. At Venator, we understand that your manufacturing processes rely on exacting specifications and tight tolerances. That’s why our team of skilled technicians is dedicated to achieving unparalleled precision in every aspect of the grinding process. From intricate geometries to critical dimensions, we have the expertise and the equipment to deliver exceptional results. Moreover, we recognize the importance of timely delivery to keep your production schedule on track. With our commitment to efficient turnaround times, you can trust Venator to meet your deadlines and ensure seamless continuity in your operations. Choose Venator for precision grinding that exceeds expectations and keeps your business running smoothly.

Our Mission: Venator Precision Grinding Inc provides the manufactures of Southern Ontario with cylindrical grinding services that exceed their expectations on both quality and delivery.

Frequently Asked Questions

What types of materials can be precision ground at your machine shop?

Our machine shop is equipped to precision grind a wide range of materials, including but not limited to metals like steel, aluminum, stainless steel, titanium, and various alloys. Additionally, we can handle non-metallic materials such as ceramics and certain plastics.

What tolerances and surface finishes can your precision grinding processes achieve?

Our precision grinding processes are capable of achieving tight tolerances, typically ranging from a few microns to a few thousandths of an inch, depending on the specific material and part geometry. Surface finishes can be tailored to your requirements, ranging from smooth finishes for aesthetics to rougher finishes for functional purposes.

Do you have experience working on projects with similar specifications to our requirements?

Yes, our machine shop has extensive experience working on a diverse range of projects, including those with stringent precision grinding requirements. We have successfully completed projects for various industries, such as aerospace, automotive, medical, and more, and we are confident in our ability to meet your specific needs

What quality control measures do you have in place to ensure the accuracy and consistency of the precision grinding results?

Ensuring quality is a top priority for our machine shop. We have rigorous quality control procedures in place at every stage of the precision grinding process. Our skilled technicians use advanced measurement tools, such as optical comparators, and surface profilers, to verify the accuracy and consistency of the ground parts. Additionally, we follow relevant quality standards to maintain the highest level of precision and quality in our work..